Vibration is a frequent and often underestimated issue in heavy industrial buildings. Facilities that rely on rotating machinery—such as crushers, screens, and compactors—regularly face dynamic forces that, if not accounted for during design, can lead to costly operational disruptions. Excessive vibration can reduce equipment efficiency, damage structural components, create safety concerns, and even lead to full shutdowns. These problems are not inevitable. In most cases, they stem from structural designs that fail to properly address vibration behavior. The root cause? A general lack of familiarity with structural dynamics within the context of industrial environments. Unlike conventional buildings, these structures demand a much more rigorous, specialized approach.

Vibration is a frequent and often underestimated issue in heavy industrial buildings. Facilities that rely on rotating machinery—such as crushers, screens, and compactors—regularly face dynamic forces that, if not accounted for during design, can lead to costly operational disruptions. Excessive vibration can reduce equipment efficiency, damage structural components, create safety concerns, and even lead to full shutdowns. These problems are not inevitable. In most cases, they stem from structural designs that fail to properly address vibration behavior. The root cause? A general lack of familiarity with structural dynamics within the context of industrial environments. Unlike conventional buildings, these structures demand a much more rigorous, specialized approach.

WHY TRADITIONAL DESIGN METHODS FALL SHORT

The engineering community often defaults to simplified vibration checks that were developed decades ago—typically by evaluating the natural frequency of one or two supporting beams. While this might suffice for floor vibration in commercial buildings, it is inadequate for heavy industrial environments. These facilities are subject to large, repetitive, and directional dynamic loads. Evaluating vibration behavior in isolation fails to capture the system-wide response of the supporting structure. A more holistic view is required—one that considers vertical and horizontal vibration responses together and understands the interaction of all structural members under operational loading. Without this level of analysis, the likelihood of design deficiencies and future retrofit needs increases dramatically.

LEVERAGING TECHNOLOGY FOR BETTER OUTCOMES

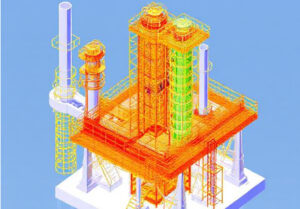

Modern tools now allow engineers to analyze and address vibration risks more precisely and efficiently than ever before. Finite Element Analysis (FEA) software can simulate how an entire structural system behaves under dynamic equipment loads. This makes it possible to predict problem areas during the design phase and adjust accordingly—before construction even begins. Additionally, accelerometers and vibration sensors can now be installed during commissioning to validate design assumptions and monitor structural behavior in real time. These technologies empower engineers to not only solve existing problems but also prevent them from occurring, ultimately leading to safer, more reliable, and longer-lasting facilities.

PROVEN THROUGH RESEARCH

Effective vibration design in heavy industrial buildings requires more than checking a few beam frequencies — it demands a full-system understanding of how dynamic loads interact with structural elements. Industry knowledge has evolved, and successful outcomes now rely on comprehensive dynamic analysis and proven modeling techniques. At RTM Engineering Consultants, our structural team stays current with emerging research and best practices to ensure vibration performance is addressed from the start. This approach has helped clients avoid retrofits, reduce downtime, and improve long-term structural resilience across a variety of industrial environments.

DESIGN SMARTER, OPERATE BETTER

Vibration issues in heavy industrial buildings are preventable with the right structural approach. Full-system dynamic analysis, applied early in design, can reduce retrofits and avoid costly disruptions. Esra Persellin, PE, Principal Structural Engineer at RTM Engineering Consultants, brings over 15 years of experience in this field, helping clients create efficient, resilient structures aligned with real-world demands.

Esra Persellin, PE

Esra Persellin, PE

Principal 15+ years of experience in structural engineering.