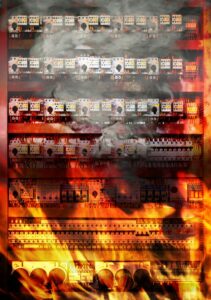

WHAT ARE ARC FLASH HAZARDS?

In today’s safety conscious environment, there is growing concern and increased discussion regarding arc flash hazards. An arc flash is a technical name for an electrical explosion – this occurs during a fault, or short circuit condition, which passes through an arc gap. An arc flash event can expel large amounts of deadly energy in the form of a super-heated ball of gas, with arc flash temperatures reaching as high as 35 thousand degrees Fahrenheit. Without proper precautions, it can have deadly or disabling consequences for workers, and cost business owners millions per case for treatment of injuries.

When workers open live electrical panels with voltage exceeding 50V, usually for the purpose of troubleshooting an issue or metering, they are exposed to arc flash hazards. Almost all buildings have these types of hazards, and it only takes a fraction of a second for the electrical explosion to produce fire, burning flesh at distances of 10 feet or more. Arc flash temperatures can also liquefy or vaporize nearby metal including copper, aluminum conductors or steel equipment parts—resulting in explosive pressure and sound waves strong enough to throw workers across the room.

To provide an increased level of safety for the electrical workers, it is crucial for those involved in the design, implementation and evaluation of electrical distribution systems to have a keen understanding of how to evaluate arc flash hazards as well as how to minimize or mitigate the situation.

Get a full copy of Arc Flash Hazards: What They Are & How to Provide a Safe Work Environment

HOW CAN I PROTECT MY WORKERS AGAINST ARC FLASH HAZARDS?

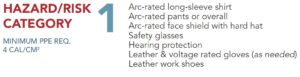

Employees who work on electrical panels can be best protected against existing arc flash hazards by working on the equipment de-energized. If de-energizing equipment is not an option due to life safety concerns, then proper electrical safety training and wearing personal protective equipment (PPE) suitable for the level of hazard that may occur at each piece of equipment is the best approach. To understand the appropriate level, an arc flash study in which a model of your electrical system is prepared can be used to quantify the hazard present at each section of equipment. Also note that most PPE gear are not to be used as the only measure of protection against hazards, and an arc flash study can help employers understand all the details surrounding compliance.

Employees who work on electrical panels can be best protected against existing arc flash hazards by working on the equipment de-energized. If de-energizing equipment is not an option due to life safety concerns, then proper electrical safety training and wearing personal protective equipment (PPE) suitable for the level of hazard that may occur at each piece of equipment is the best approach. To understand the appropriate level, an arc flash study in which a model of your electrical system is prepared can be used to quantify the hazard present at each section of equipment. Also note that most PPE gear are not to be used as the only measure of protection against hazards, and an arc flash study can help employers understand all the details surrounding compliance.

PERSONAL PROTECTIVE EQUIPMENT

WHAT IS AN ARC FLASH STUDY AND WHY DO YOU NEED IT?

RTM offers arc flash studies and analyses, but we often find that building owners don’t understand what they entail or why they are important. An arc flash study determines how much electrical energy is available at each piece of electrical equipment, the more available energy, the greater the arc flash potential, and the greater the risk to life safety.

When installing a new system or making modifications to a building’s electrical infrastructure, OSHA (Occupational Safety and Health Administration) requires companies to have an arc flash study performed to provide a safe work environment. OSHA’s main goal is to expose any hazards that exist within a facility. Workers that are aware of the hazards and trained to deal with them

are less likely to be injured.

Arc flash survey results, including arc flash distances and incident energy potential, should be labeled on the equipment so that workers who maintain it will understand how to best protect themselves. The level of incident energy is provided on the label to allow the trained worker to pick the best PPE for each situation.

RTM provides turnkey arc flash studies and can train engineers and electricians in your building to help ensure ongoing arc flash compliance. Our team also performs electrical system studies that include a report that details results, updated electrical one-line diagrams, recommendations, and a prioritized action plan.